Let us Take Care of Your Injection Molding & Extrusion Needs

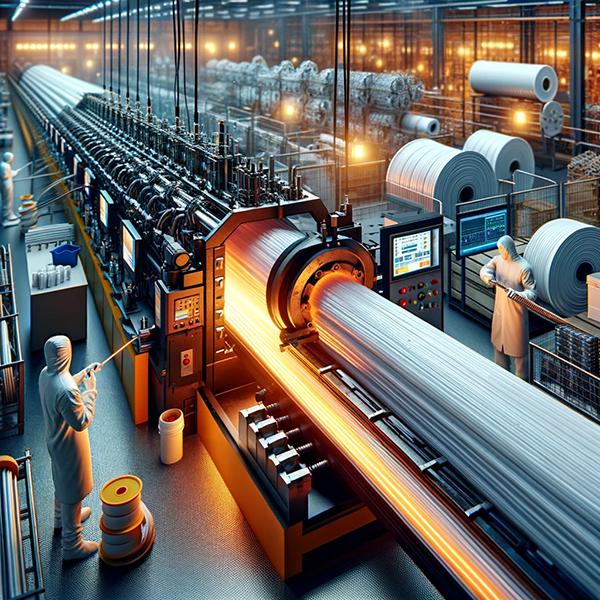

At Paymaker, our injection molding & extrusion services stand out for their exceptional quality and efficiency. Harnessing state-of-the-art technology, we deliver precision-engineered products tailored to diverse industry requirements. Our expert team, skilled in handling a variety of materials, ensures each product meets the highest standards of strength and durability. We pride ourselves on our ability to produce complex shapes with remarkable consistency, maintaining tight tolerances essential for high-quality outputs that are highly reliable and customer-centric.

What Exactly is Injection Molding & Extrusion?

Injection molding and extrusion are two key processes in the manufacturing of plastic products. Injection molding involves melting plastic granules and injecting them under high pressure into a mold, where they cool and solidify into the desired shape. This method is ideal for producing high volumes of identical parts with precise dimensions, such as toys, automotive components, and medical devices.

Extrusion, on the other hand, is a continuous process where plastic material is melted and pushed through a die to create long, continuous shapes like tubes, pipes, or profiles. It’s particularly suited for creating products with a consistent cross-sectional profile. Both techniques are essential in the plastics industry for their efficiency, versatility in shaping various materials, and ability to produce complex designs with high precision.

Industries we serve:

Our Injection Molding and Extrusion Capabilities

Why Choose Paymaker for Injection Molding & Extrusion?

Our professionals are highly trained and experienced in the latest injection molding & extrusion techniques.