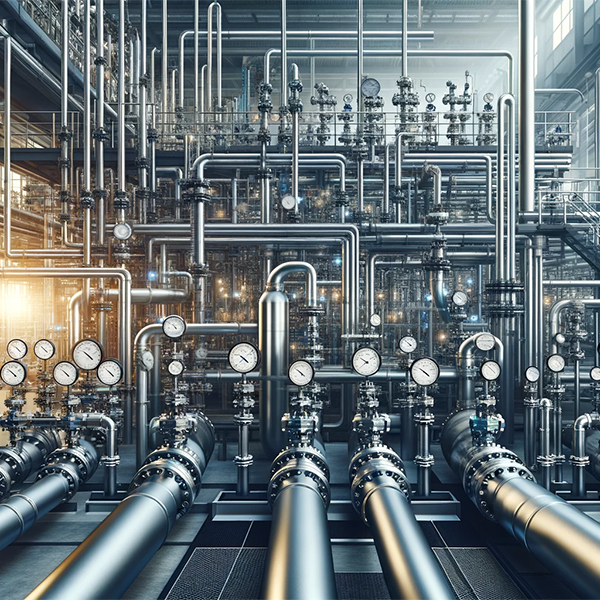

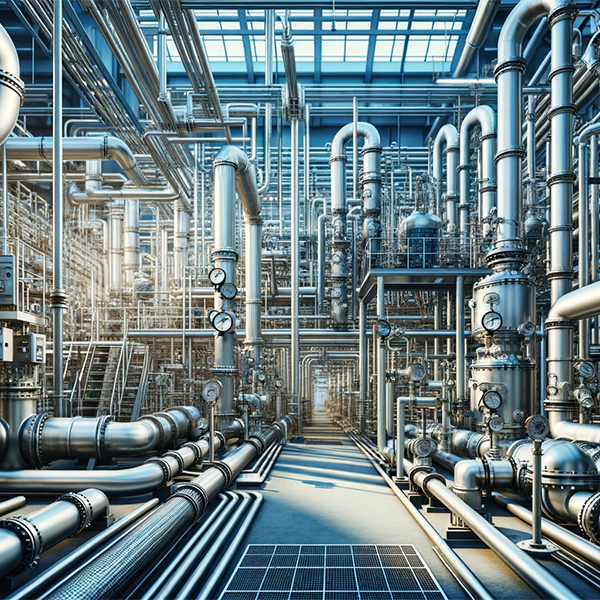

Industrial Piping Specialists for all of Your Manufacturing & Construction Needs

Industrial piping systems are the lifelines of virtually all industries – from manufacturing and power generation to pharmaceuticals and petrochemicals. They are designed to transport a multitude of substances such as water, chemicals, gases, and waste, ensuring operational efficiency and safety. Understanding the intricacies of industrial piping is key to optimizing any industrial operation. That’s where our experienced team comes in!

Piping Materials: Strength and Compatibility

The material selection for industrial pipes varies based on the application and the substances being transported. Common materials include:

Steel and Stainless Steel: Known for their strength and durability, ideal for high-pressure and high-temperature applications.

PVC and CPVC: Lightweight, corrosion-resistant options suitable for chemical and wastewater transportation.

Copper: Best for heat and electrical conductivity, commonly used in HVAC systems.

Industries we serve:

Types of Industrial Piping Systems

Why Choose Paymaker for Your Industrial Piping Solutions?

We know that proper installation and regular maintenance of industrial piping systems are crucial for operational efficiency and safety.